Concrete not gaining proper strength? Is your SCM a true pozzolan?

Often powders and materials used in concrete are not first examined by XRD, minerology or thin-section microscopy to determine if the powders will be an appropriate SCM.

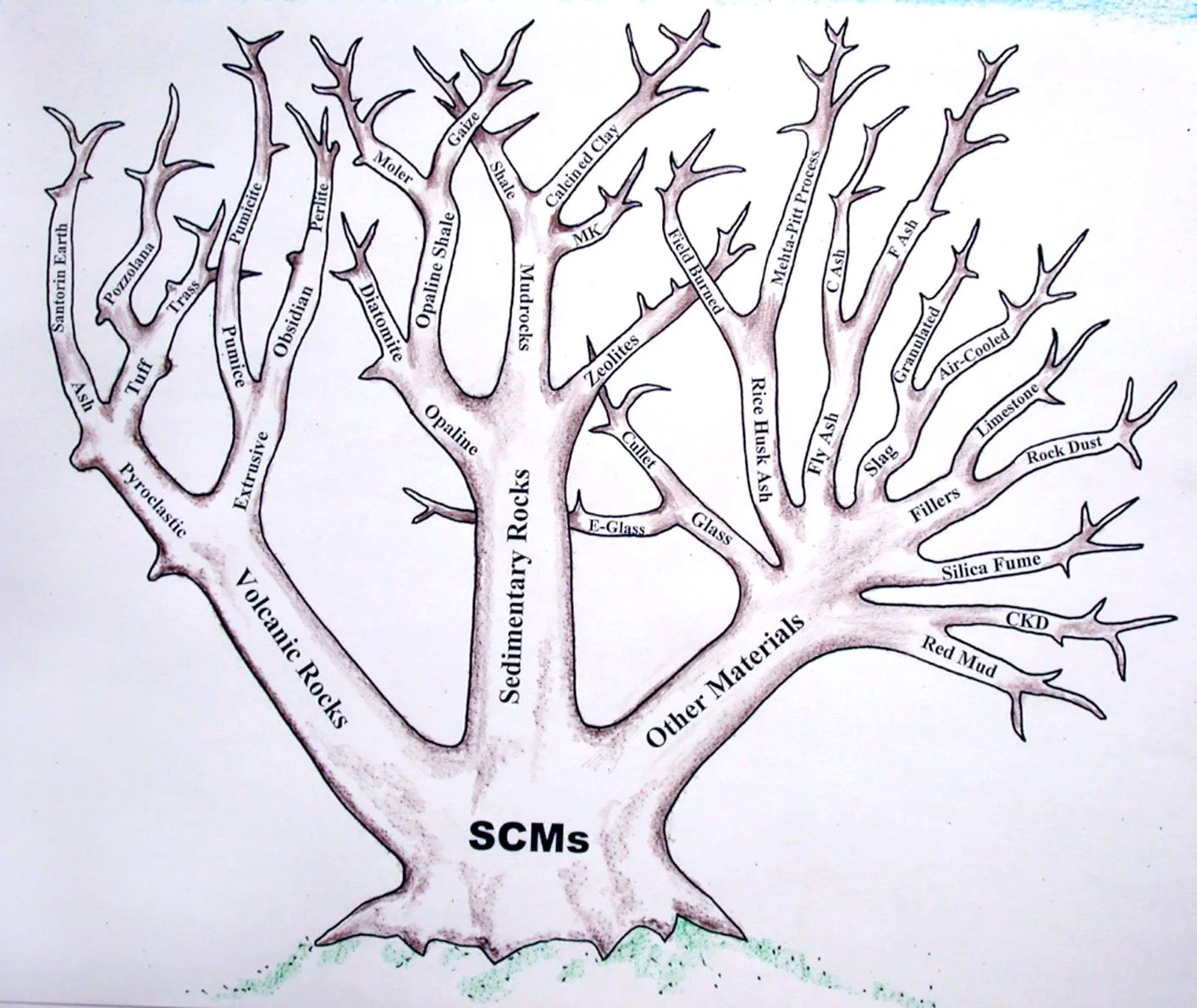

Powders used in the concrete industry which include cement and supplementary cementing materials (SCMs), also known as mineral admixtures. SCMs are a range of powders added to concrete to replace cement and provide added strength and durability through the pozzolanic reaction.

Mineral powders used in concrete range from highly active pozzolans to mineral fillers, known as dust of fracture, that are not pozzolanic, but are used as cement replacements and viscosity modifying admixture additions that serve only to facilitate particle packing in the concrete paste and enhance early nucleation of hydration products.

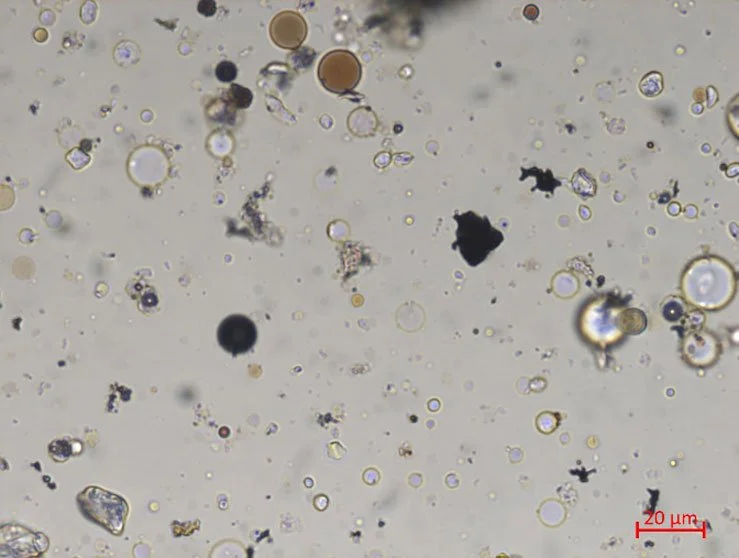

Class F fly ash is shown in an immersion slide to be tiny glassy spherical particles.

Pozzolanic materials react in concrete to convert the weaker phase calcium hydroxide (portlandite) to the stronger binding material calcium aluminum silicate hydrate that makes concrete the strong and durable material it is.

SCMs are pozzolans which do not have cementitious properties by themselves, but must be activated in the alkaline environment of portland cement.

When properly cured concretes with pozzolans will continue to build strength long after straight cement mixtures have reached their ultimate strength.

The classification of SCMs shown as a tree, with a wide range of materials being used in concrete.

The non-pozzolanic dust of fracture powders do not contribute significantly to early strength gain, other than the effect of packing and nucleation enhancement, as they do not react with portlandite to make cementitious products. The only exception is the use of limestone powder addition to cement in which not only packing and nucleation effects are at work, but there are also early carboaluminate hydration phases that form providing some early strength gain.

The dust of fracture powders, including limestone powder, are not pozzolans, as they do not react with portlandite to build long-term strength in concrete.

Only pozzolanic materials containing significant amorphous material such as volcanic glass or opal, properly calcined clays, or zeolite-rich ash and tuff are true pozzolans that build additional strength in concrete that is cured.

Pictured -A glassy dacite from Arizona is a good candidate for use as a pozzolan.

Active pozzolans differ from dust of fracture fillers in that they continue to build concrete strength beyond the point at which straight cement mixes stop increasing in strength.

Example of an active pozzolan. Pumice from Santorini in the Aegean Sea formed during the eruption of Thera volcano that led to the demise of the Minoan culture is shown. This material is the pozzolan known as Santorin Earth and is still used today.

Testing Concrete for Powders

Thin Section Microscopy

Thin section images of the glassy Arizona dacite is seen in plane light on the left and with crossed polars on the right. The gray alkali feldspar and brown biotite comprise a small modal percentage of the rock, so when ground it is expected to be a good pozzolan.

The Most definitive evaluation of your concrete to discover if proper SCMs were used is an examination of samples using powder X-ray diffraction (XRD) and thin section microscopy to determine mineralogy, evaluate the amorphous content, and give the proper nomenclature to the materials.

The ultimate performance metric for a pozzolan is strength increase shown in triplicate cylinder breaks at 56 days and beyond.

Prescott Petrographics Sample: XRD pattern of Class F fly ash shows the typical crystalline phases superimposed on the diffraction maxima that represents the amorphous material in the sample. This fly ash contains more than half glassy material.

ASTM C618 mortar cube breaks are not definitive, as they can pass the pozzolan test even with dust of fracture powders (which does not gain strength the same way as active pozzolans).

Did your concrete not gain adequate strength?

Prescott petrographics can determine the weight percent of fly ash and slag in hardened concrete & in blended cements to uncover powder issues.

Suspect your concrete did not have the proper powders used in the mixture?

We can determine the weight percent or fly ash slag in hardened concrete for scientifically exacting answers.